2025-10-22 3234 0

近日,江苏泰信机械股份有限公司(以下简称“泰信机械”)研制的卡特彼勒底盘旋挖钻机KR220C在中泰铁路桥梁工程及清莱府重大基建项目现场,凭借出色表演,成为破解当地复杂地质的核心设备之一。这款“桩基础施工专家”不仅精准匹配现场桩体施工需求,更在从沙土到中风化岩层的多元地质中实现高效钻进,单设备出勤率超95%,为两大项目缩短工期、提升施工质量提供关键支撑,成为中国装备赋能东南亚基建的典型案例。

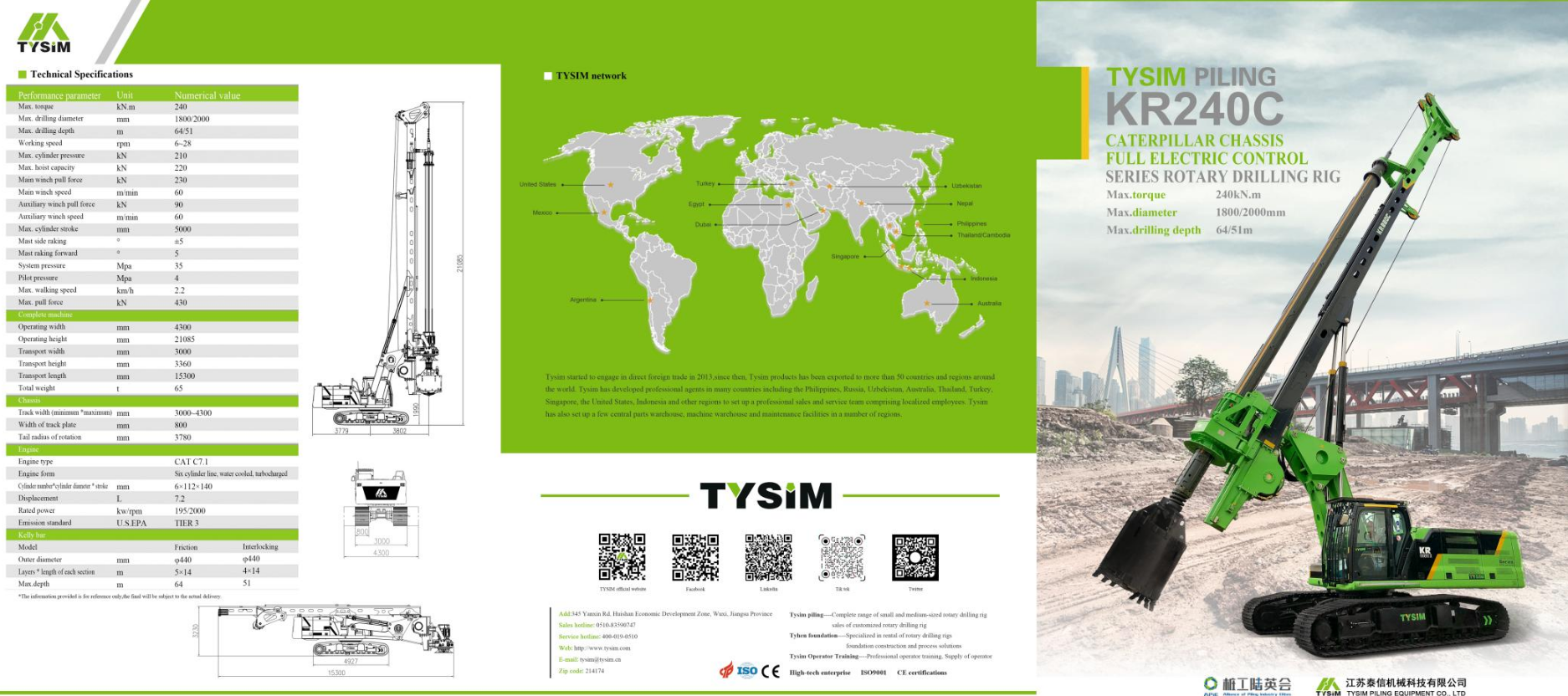

Recently, at the construction sites of the China-Thailand Railway Bridge Project and the major infrastructure project in Chiang Rai Province, the KR220C rotary drilling rig with CAT chassis of TYSIM Piling Equipment Co., Ltd. (hereinafter referred to as "TYSIM") has become a core equipment for solving local complex geological problems by virtue of its 220kN·m maximum output torque and intelligent adaptation capability. This "pile foundation expert" not only accurately meets the construction requirements for pile bodies with a diameter of 1000mm, but also achieves efficient drilling in diverse geologies ranging from sandy soil to moderately weathered rock formations. With a single equipment availability rate of over 95%, it provides key support for shortening the construction period and improving the quality of the two projects, and has become a typical case of Chinese equipment empowering infrastructure construction in Southeast Asia

双项目攻坚:复杂地质下的效能突围 Dual-Project Campaign: Efficiency Breakthrough Under Complex Geological Conditions 中泰铁路桥梁桩工程需攻克 “1-9米白色沙土层 + 10-33米淤泥层 + 34-39米强风化红砂岩” 三层复杂地质,且桩体要求1米直径、39米深。面对如此复杂地质难题,KR220C通过智能电控系统实时调节钻进参数:沙土层中以每小时 3.5 米速度连续钻进无塌孔;淤沙泥层依托液压功率智能分配技术,单桩穿越耗时缩短 2.5 小时;强风化红砂岩段启动一键入岩模式,以每小时 1.2 米速度精准嵌岩。如上施工效率较传统设备提升30%,同时沉渣厚度控制在 50mm 内,成孔合格率 100%。 For the bridge pile project of the China-Thailand Railway, three complex geological layers need to be overcome: 1-9m white sand layer, 10-33m muck layer, and 34-39m strongly weathered red sandstone. The piles require a diameter of 1000mm and a depth of 39m. To address these geological challenges, the KR220C adjusts drilling parameters in real time via its intelligent electronic control system: it drills continuously at 3.5m/h in the sand layer without hole collapse; in the muck layer, it uses intelligent hydraulic power distribution technology to reduce the single-pile penetration time by 2.5 hours; in the strongly weathered red sandstone section, it activates the one-click rock entry mode for accurate rock embedding at 1.2m/h. Its construction efficiency is 30% higher than that of traditional equipment, while the sediment thickness is controlled within 50mm and the hole formation qualification rate reaches 100%. 同期推进的清莱府项目,桩体深度达51米、直径1米,地质涵盖沙土、强风化白沙岩与中风化白沙岩。KR220C锁杆式钻杆适配极限深度需求,表层沙土保持每小时3米钻进效率,强风化岩层中垂直度偏差小于1/300;面对最坚硬的中风化白沙岩,其220kN・m扭矩配合多级减震设计,实现每小时 0.8 米钻进速度,较当地设备提升40% 以上。最终单台设备日均完成2根51米深桩,提前两周完成阶段性任务。 In the same period, the Chiang Rai project requires piles to be 51m deep and 1000mm in diameter, with geological conditions including sand, strongly weathered white sandstone and moderately weathered white sandstone. The KR220C rod-locking drill pipe meets the ultra-deep requirement: it maintains a drilling efficiency of 3m per hour in the surface sand layer, and the verticality deviation is less than 1/300 in the strongly weathered sandstone. For the hardest moderately weathered white sandstone, its 220kN・m of torque, combined with multi-stage shock absorption design, achieves a drilling speed of 0.8m per hour—over 40% higher than local equipment. Eventually, a single unit completed 2 piles (51m deep each) daily, finishing the phased task two weeks ahead of schedule. 效能背后:技术与服务双支撑 Behind the Efficiency: Dual Support from Technology and Services KR220C 的高效表现,源于“硬件 + 软件 + 服务”的全链条保障。硬件上,卡特彼勒发动机与底盘提供强劲动力与稳定作业平台,适应东南亚雨季泥泞场地;软件上,全电控系统可针对不同地质自动优化扭矩、加压参数,避免无效能耗。更关键的是,泰信机械同步派驻售后工程师现场指导,提供参数调试与维护服务,确保设备在两大项目中综合故障率低于 5%,为高效施工扫清障碍。 The high-efficiency performance of the KR220C stems from full-chain support covering "hardware + software + service". In terms of hardware, its Caterpillar engine and chassis provide strong power and a stable operating platform, adapting to muddy sites during Southeast Asia's rainy season. For software, the full electronic control system automatically optimizes torque and pressure parameters for different geological conditions, avoiding unnecessary energy consumption. More importantly, TYSIM simultaneously dispatches after-sales engineers for on-site guidance, offering parameter adjustment and maintenance services. This ensures the comprehensive failure rate of the equipment in both projects is below 5%, clearing obstacles for efficient construction. 国际认可:中国装备深耕东南亚 International Recognition: Chinese Equipment Deepening Presence in Southeast Asia “KR220C完美解决了泰国复杂地质施工痛点,效率远超预期。” 中泰铁路泰方施工负责人评价道。此次双项目攻坚,不仅延续了该设备在乌兹别克斯坦、土耳其等国的出色表现,更印证了中国桩工设备的国际竞争力。随着中泰铁路等互联互通项目推进,KR220C这类 “高效、可靠” 的中国装备,正成为东南亚基建市场的优选,为区域合作筑牢技术根基。 “KR220C has perfectly addressed the construction pain points in Thailand's complex geological conditions, with efficiency far exceeding expectations," commented the Thai construction director of the China-Thailand Railway. These two project challenges have not only continued the equipment's outstanding performance in countries like Uzbekistan and Turkey, but also confirmed the international competitiveness of Chinese piling equipment. As connectivity projects such as the China-Thailand Railway move forward, highly efficient and reliable Chinese equipment like the KR220C is becoming the preferred choice in Southeast Asia's infrastructure market, laying a solid technical foundation for regional cooperation.

Hot News

成功提示

成功提示

错误提示

错误提示

警告提示

警告提示

评论 (0)